Solar Water Purifier

Water purification process undergoes the process of removing solid wastes, biological contaminants, unwanted chemicals from contaminated water. This water purification is for human consumption and may be for some other specific purposes. This purification process many levels of filtration to meet the exact requirement.

Benefits:-

1. Health benefits

2. Controls outbreak of dangerous bacteria

3. Filter out more contaminants

4. Clean and mineral-rich water

5. Control of your water quality

6. Protection against toxins

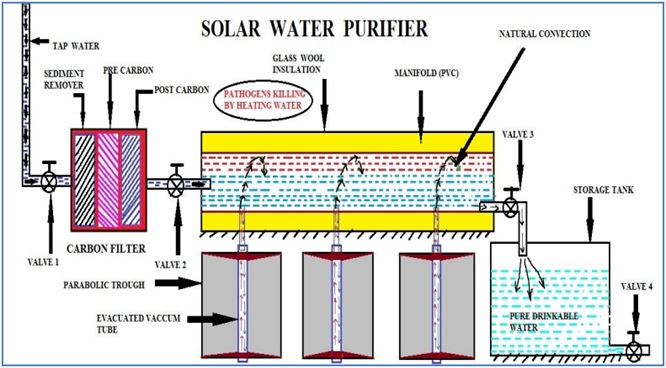

Layout of solar water purifier

Components of solar water purifier

[1] Parabolic reflector: A parabolic trough is a type of solar thermal collector that is straight in one dimension and curved as a parabola in the other two, lined like a polished metal mirror. The energy of sunlight which enters the mirror parallel to its plane of symmetry is focused along the lines, where objects are positioned that are intended to be heated.

[2] Vacuum tube: An evacuated vacuum tube collector consists of two concentric glass tubes with annular space between them being evacuated. The outer surface of inner glass tube is selectively coated. The incoming solar radiation is absorbed on this surface and partly conducted inwards through the tube walls. The inner tube is filled with water and the heat is transferred to the water by thermo syphon circulation. Due to surrounding vacuum the heat loss by convection to surrounding is significantly reduced.

[3] Metal construction: The construction of ribs to hold the SS reflective sheet is made using aluminum and the cutting of ribs is done by laser cutting method. The stand to hold the manifold and tank is constructed of mild steel.

[4] Manifold: Capacity of manifold is 27 liters and is made by PVC. Its outer diameter is 140mm and wall thickness is 3.4mm.The manifold has an outer layer of glass wool in order to prevent heat loss. The thickness of the layer is 30mm.

[5] Carbon Filter: The Carbon filter has 3 parts, which are sediment removal, pre-carbon and post-carbon filter. In first part sediments are removed and then other aesthetics like colour and odour are controlled by pre and post carbon filter. The processing capacity of the filter is 3.7 LPM.The filter can effectively remove sediment particles of size0.5 to 50 micrometers.

Materials:-

1. The side and bottom walls need to be insulated. This can be achieved by using multilayered insulator. Glass wool will be sand-witched between two metallic plates. This will ensure negligible heat loss to the surroundings.

2. The main frame is composed of steel owing to its corrosion resistance, low weight, long life and easy cleanability.

3. The outside of the complete distiller is coated with carbon black to increase absorption of radiation.

4. The cover on the top is made of tempered glass so that the birds can’t see their reflection and hence avoid nuisance.

Usage:-

The usage will involve following steps:-

1. The user will fill the reservoir tank with water that needs to be purified.

2. Attach the vacuum pump to the apparatus and operate it till the pressure inside drops to around 20kPa. Then remove the pump.

3. Attach the pipe for collecting the purified water.

4. Then he will lift the whole device up a few meters above the ground (around 2.5 m). This will ensure no shadows fall on the apparatus during any part of the day.

5. Leave it there till evening.

6. Remove the purified water for use.

7. Remove the plates for cleaning and dispose of the remaining water.

8. Ready for use on the next day.

Maintenance:-

1. The only maintenance that the device requires is replacement of the glass in case of accidental breakage.

2. Daily cleaning of the plates is required.

3. Sometimes the pump will need to be oiled and serviced. This cost might occur once in 6 months or so.

Cost Analysis:-

The total area of the steel plates used = 4.5 m2

Rate of steel plate of thickness 1mm = 60/Kg

Total cost of steel = Rs 400

Cost of crushed hay and sawdust = Almost free

Cost of carbon black paint = Rs 20

Cost of tempered glass = Rs 200

Cost of insulation and sealing = Rs 80

Cost of the pump = Rs 100

Cost of the hoisting mechanism and other auxiliaries = Rs 50

Cost of labor and machining = Rs 130

Net cost of the device = Rs 980